R07 riser safety notice

Description of the R07 riser:

The semi light riser R07 is offering an ergonomically optimized C handle position and a “floating B”.

It is a straight forward and very clean design with the target to reach easy handling and good length stability.

It is offering ball bearing pulleys on every transition.

DHV Safety notice:

Date 11.01.2024

Subject Paraglider PHI ALLEGRO X-Alps 20 DHV GS-01-2617-21, PHI ALLEGRO X-Alps 21 DHV GS-01-2618-21, PHI ALLEGRO X-Alps 22 DHV GS-01-2619-21, PHI ALLEGRO X-Alps 24 DHV GS-01-2620-21, PHI ALLEGRO X-Alps 17 DHV GS-01-2630-21, PHI ALLEGRO X-Alps 19 DHV GS-01-2631-21, PHI MAESTRO 2 19 DHV GS-01-2701-22, PHI MAESTRO 2 21 DHV GS-01-2702-22, PHI MAESTRO 2 22 DHV GS-01-2703-22, PHI MAESTRO 2 23 DHV GS-01-2704-22, PHI MAESTRO 2 25 DHV GS-01-2705-22, PHI MAESTRO 2 17 light DHV GS-01-2735-22, PHI MAESTRO 2 18 light DHV GS-01-2736-22, PHI MAESTRO 2 19 light DHV GS-01-2737-22, PHI MAESTRO 2 22 light DHV GS-01-2738-22, PHI MAESTRO 2 23 light DHV GS-01-2739-22, PHI MAESTRO 2 25 light DHV GS-01-2740-22, PHI MAESTRO 2 21 light DHV GS-01-2741-22

PHI Paragliders has issued a safety notice concerning PHI paragliders with the R07 risers. On these risers, the B-plane is suspended from the riser with an 800 daN Technora line. On a PHI ALLEGRO X-Alps 20, year of manufacture 3/2021, the B-line suspension on the riser broke during flight. The pilot was able to make an emergency landing and remained uninjured.

PHI orders an inspection of the risers by the owner and offers to replace damaged components. This measure must be carried out before the next flight.

For a PHI ALLEGRO X-Alps 20, manufactured in 03/2021, the B-line connection on the riser broke during flight. This suspension is made from an 800 daN (800 kg) Technora line from Edelrid.

Presumably the friction on a sharp edge of the pulley (Ronstan brand) caused damage to the line and weakened it to the point of breaking. When it comes to share movement, there is a series variation among the rollers used.

Pulley with sharp edges: Figure 1.

Broken, heavily worn (rubbed) line: Figure 2

The pilot was able to make an emergency landing and was uninjured in the incident.

From the visual impression of the risers, the paraglider in question was very heavily used. There are clear signs of abrasion on the line.

To be on the safe side, the manufacturer issues the following safety notice:

The R07 risers on the models ALLEGRO X-alps (later ALLEGRO light), MAESTRO 2 light, and MAESTRO 2, as well as all other PHI models that are equipped with the optionally available R07 risers (Figure 3) must be subjected to a visual inspection.

The check can be carried out by the owner by themselves and must be carried out before the next flight.

If damage or excessive wear is discovered, the owner is requested to stop flying the affected paraglider and contact PHI or their PHI dealer about replacing the affected line and, if necessary, the pulley.

Web: https://phi-air.com/

E-mail: info@phi-air.com

Tel: +43 676 3805203

Tel: +43 676 6007501

How could it happen?

Even the EDELRID 8001-800 is a 100 times over dimensioned, it is a TECHNORA line with the pro and contras of that material.

EDELRID 8001 TECHNORA lines are used as rigging lines on nearly every high performance wing of all manufacturers.

The argument for TECHNORA is the length stability.

The argument against these ARAMID fibre is the fact, that it is losing strength by time.

Everyone knows that, so there is established system of 2 years checks and breaking strength tests for ARAMID lines.

The wing that had the broken line was nearly 3 years old and had more than 300+ hours of usage in a demanding UV intense area (California).

There has no complete 2 years check been done.

How often yet?

This was the first time this lines broke. One of more than 1500 R07 risers.

General life time of that line:

The general life time depends on conditions and usage. In a demanding scenario, the life time is 200 hours of using / 2 years. Whatever happens earlier.

During a 2 years check it is on the check expert to evaluate the condition of the line: see example photos below.

As part of the pre-flight check, every pilot is urgently required to check their equipment carefully. Especially the critical load-bearing components such as risers, lines and harness with all connection elements (see manual).

What to look for:

- abnormal use of the line (hairy surface, cuts, lose fibres, faded color, general bad look, salt, sand or dirt inside,…)

- the color fading of the red sleeve around the A risers is a good indicator for UV exposure: see difference color between the red cloth of the cover (got whitened) and the red sewing: see example photos

When the 8001-800 line looks bad:

-ask your service expert.

What you need to provide to us to get the right replacement lines:

Wing model, size and serial number.

To check the revision of the R=7 risers, we need photos of the C handle area:

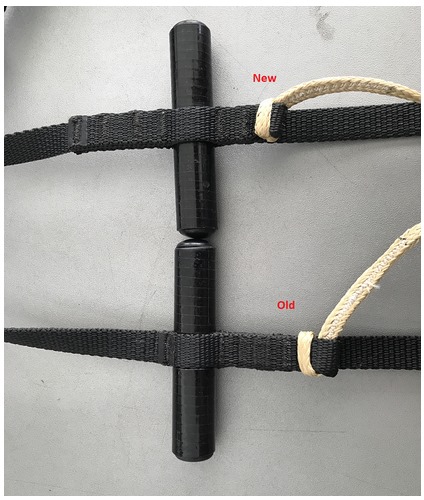

There is revision A (OLDER): 5 bartacks above the C handle: see picture

-and revision B (NEWER): 2 bartacks above C handle

Photos of both B riser lines and complete risers

Pictures to evaluate the condition of the 8001-800 transition line:

This is the original broken line.

See the strong color fading on the A riser covers. When new, the red of the cover and the sewing thread match.

The wing has almost 3 years and 300+ hours including winching, etc.

The pilot made no full 2 years check after 2 years of usage!

Edelrid 8001 lines are as well used as rigging line on nearly every high performance wing.

They are losing strength by time! We have to inspect them and to replace them in an estimated time interval of 200hours, depending on usage conditions.

That is the reason line break tests are obligatory during a 2 years check.

The wing is losing airworthiness when not checked every 2 years!

Examples for lines to be replaced:

Here some photos of lines on gliders that had 300+ hours. We recommended the pilot to replace.

Other pictures for what to search as a defective line:

This here looks like the Edelrid 8001-800 line being damaged (burned) by the main brake line during ground handling.

We often see this kind of damages on risers. People have to take care when the do ground handling or backwards takeoff not to pull the brakes when the risers are twisted.

Possible solution but limiting the R07 functions:

An additional line connecting the C riser with the floating B can give the pilot an additional feel of safety.

This connection is limiting the function as it is not possible to pull the wing “below zero” trim in normal unaccelerated setting (all risers same length).

-the could be a limitation, but also a “safety feature”, preventing wing to stall.

We are offering this line as an additional, optional part.

Additional Info: what is the requested strength in flight?

The nominal strength of the EDELRID 8001-800 line is 800DaN (around 800kg).

This line is running through a 1:3 transition which is supporting the B riser.

The lines on that B riser typically are:

MAESTRO 2 23: 1 LIROS PPSLS 260, 1 EDELRID 8001-135: in total 395kg nominal strength

ALLEGRO 24: 3 LIROS PPSLS 180: overall 540kg nominal strength

ALLEGRO X-alps 24: 1 LIROS PPSLS 260, 1 PPSLS 180: overall 440kg Nominal strength

The 8001-800 is laid 3 times and would therefore have a nominal strength of 2400kg!

In order for the B-belt to break on a MAESTRO 2 23 (before the lines hanging from the top), the 8001-800 would have to degrade to 395 / 3 = 131.7kg!

That would be only 16.5% of their nominal strength!

ALLEGRO 24 540 / 3 = 180kg = 22.5% nominal strength

ALLEGRO X-Alps 24 440 / 3 = 146.7kg = 18.3% nominal strength

To be on the safe side, we calculate with a load distribution of 50% on the B. This means that with a 130kg fixed weight, the maximum load on the B would be 32.5kg in normal flight! That would be 10.8kg on the triple 8001-800!

If you extrapolate this to 14g, that’s 151.7kg: 19% of the nominal strength.

Both approaches show that the 8001-800 line would have to degrade extremely in order to have a “mathematical problem” (14g)!

It would have to lose over 3/4 of its nominal strength!

For normal flight it would be oversized by a factor of 74.1 at a wing’s loading of 130kg! 800 / 10.8 = 74.1

-this on the assumption that B would have to bear 50%: it does not: A bears the main load.

Final words:

Paragliding ist still aviation!

We have to accept the fact that our flying machines won’t last forever!

The materials used have a lifespan (300h).

-and are not indestructible!

A careful preflight check and regular checks according to the manufacturer are essential!